Motivation

Increasing noise pollution in urban areas makes it necessary to rethink sustainable materials for room acoustics. (Astrauskas et al., 2020) Conventional acoustic materials often consist of plastic foam and are difficult to recycle. Silent Silhouettes examines clay as a building material – a traditional material that is currently seeing a resurgence in architecture. While its climate-regulating and hygrothermal properties are well documented, little is known about its acoustic potential. (Fischer et al., 2021) This is precisely where the work comes in, exploring the possibilities of using additive manufacturing to develop clay into an effective sound absorber.

Background

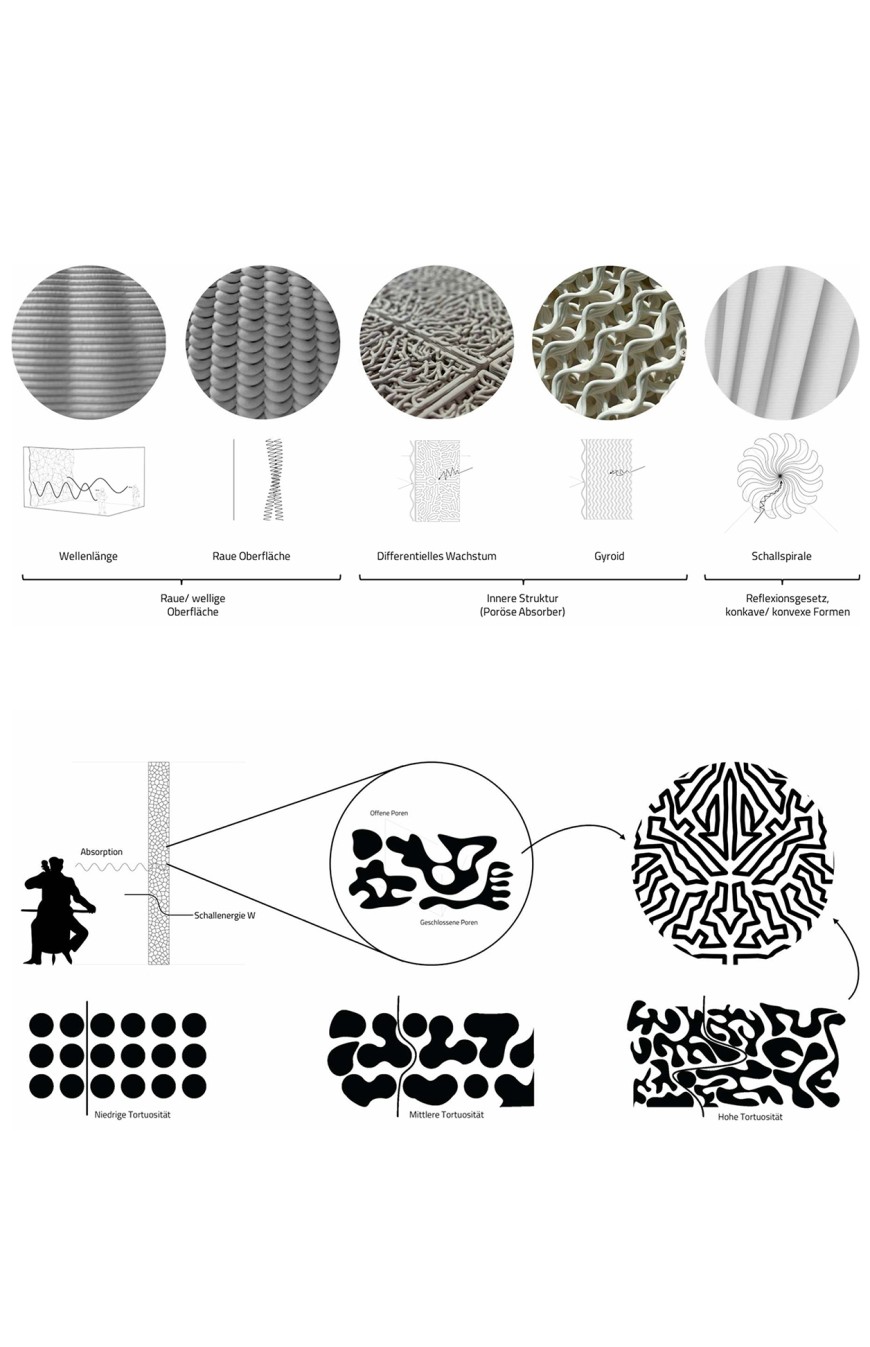

As part of comprehensive research, both the state of research on additively manufactured clay structures and the acoustic properties of other porous materials were investigated. From this, acoustic structures were derived that are acoustically effective not because of the material, but because of their geometry.

With a density of 1,800 to 2,200 kg/m³ and an average sound absorption coefficient of 30%, clay does not initially exhibit any sound-absorbing properties and thus falls into the second-worst of a total of six classes as an acoustic absorber according to the DIN EN ISO 11654 standard. (DIN EN ISO 11654: 2018-05)

However, research confirms the influence of geometry on sound absorption. (Setaki et al., 2014) This considers additive manufacturing, which makes it possible to create individual and complex structures. (Suárez and Espinosa, 2020)

While the lack of sound absorption properties means that there are no material-related advantages, the structure resulting from the additive manufacturing process offers great potential. The idea of creating a porous absorbing structure through clay 3D printing became a central component of this work. Particular attention was paid to the question of how the so-called tortuosity—i.e., the intricacy of the internal pore structure—influences sound absorption and how this can be implemented geometrically.

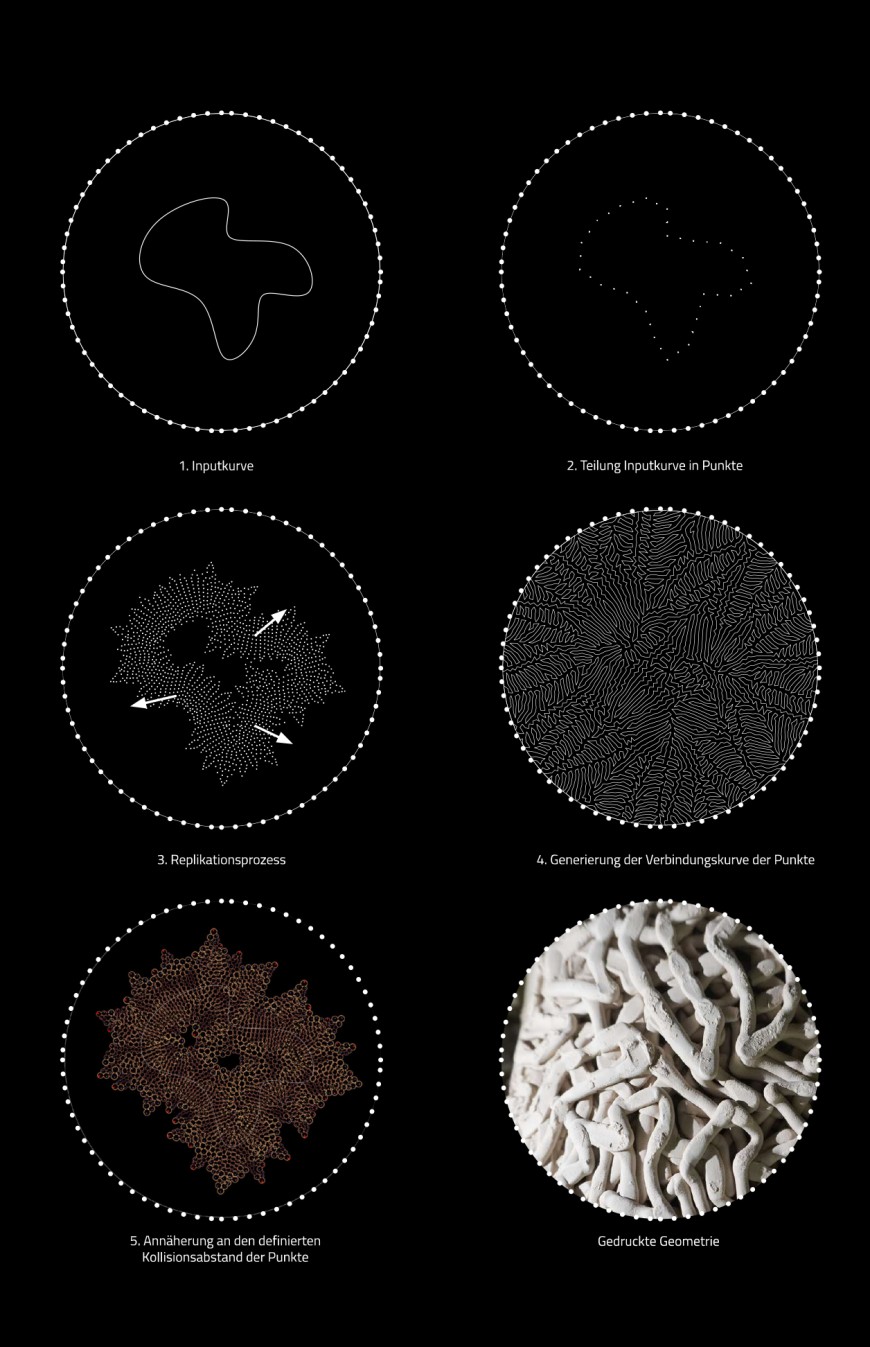

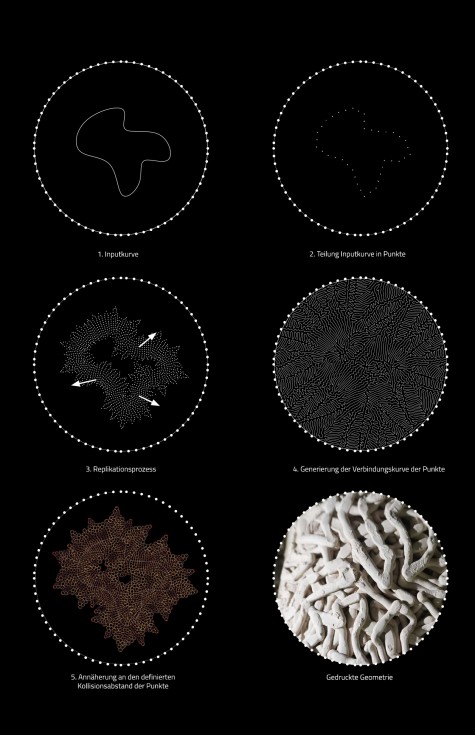

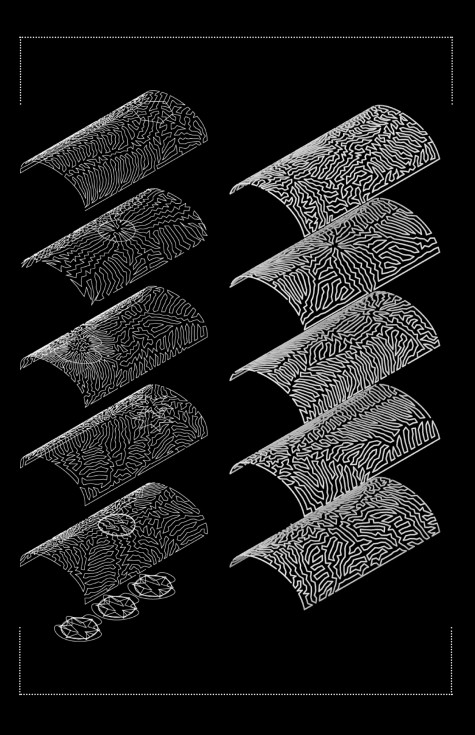

Differential Growth

A key tool of the project is an algorithm that uses the principle of differential growth. The starting point is a curve that is divided into points and produces new branches in a replication process. This creates a channel-like structure that generates connected pores and thus avoids closed ones. When several of these curve systems are superimposed, a complex three-dimensional pore space develops. To optimize the superimposition and avoid predetermined breaking points, a syntax was developed that works with different curve inputs and placements. The geometry thus exhibits a high degree of tortuosity, which has been proven to have a positive effect on acoustic effectiveness and is also particularly suitable for additive manufacturing with clay.

Form finding

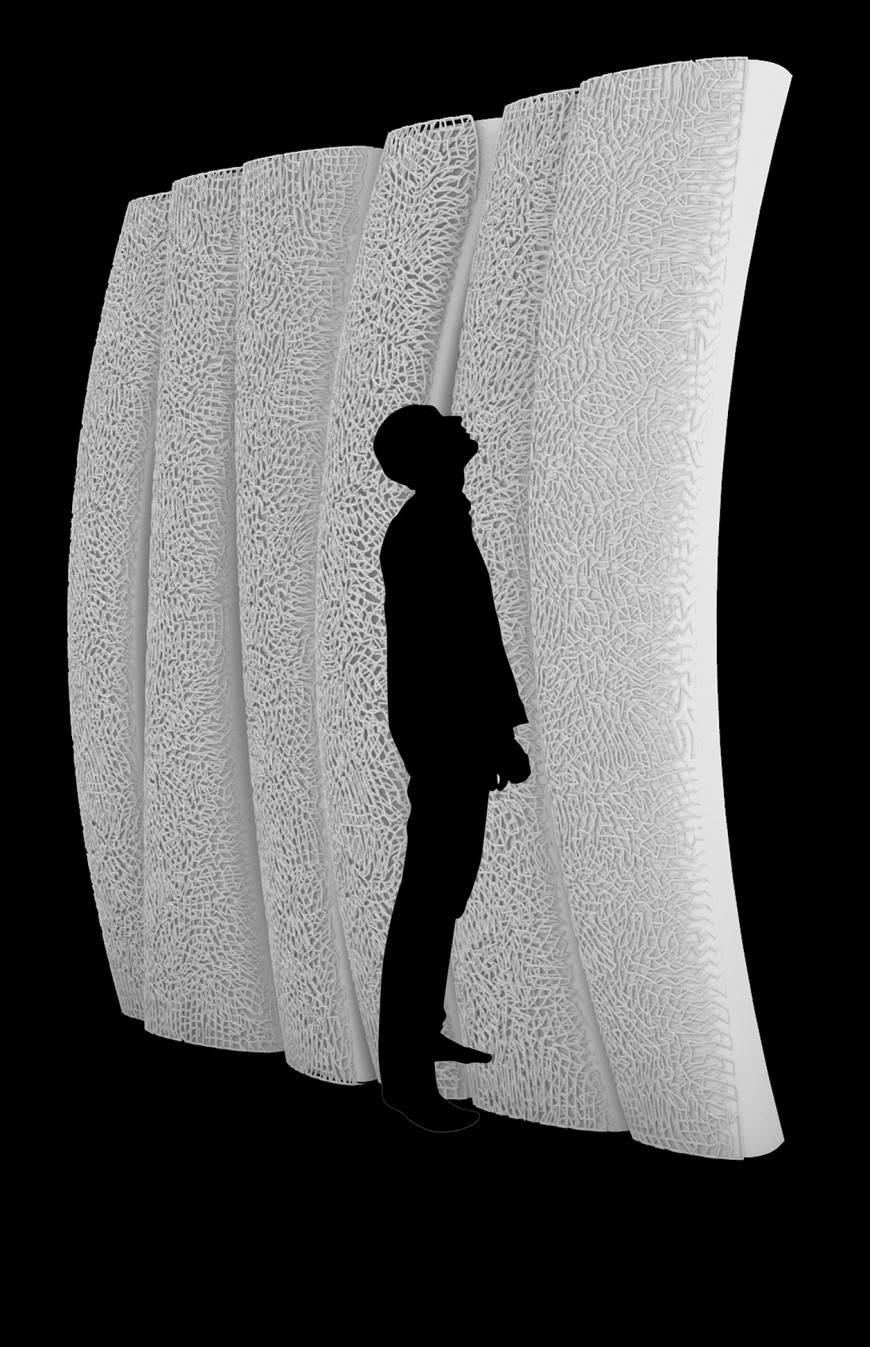

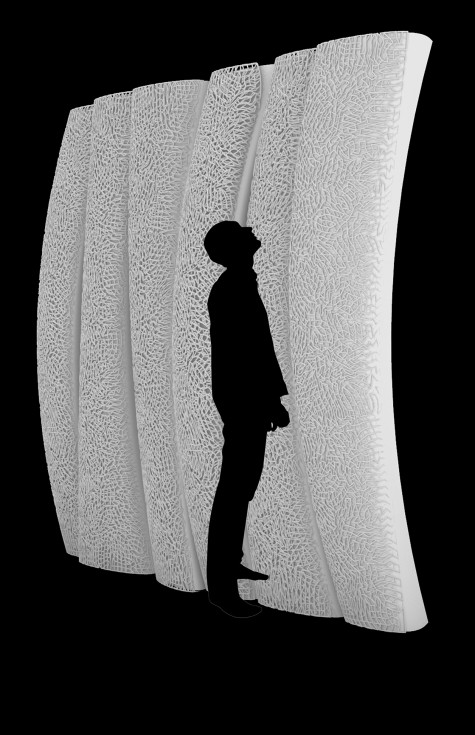

The shape of the prototype was created by combining two acoustic principles. First, a material-saving and self-supporting main structure was developed, consisting of alternating concave and convex curves. Narrow vertical openings direct the sound into the interior, where it is weakened by multiple reflections. Secondly, this system was combined with the porous geometry of differential growth, which absorbs sound precisely at the points where it had previously been concentrated. This resulted in a self-supporting, acoustically effective geometry that achieves a high absorption area despite the reduced use of material.

Prototype

Since the growth pattern could only be printed stably in a horizontal position, it was not possible to produce the entire piece in a single printing process. The clay 3D printer used (WASP 40100) was not capable of reproducing the complexity of the designed geometry in terms of freedom of movement and nozzle guidance. For this reason, the main structure and growth pattern were produced separately and, after a three-day drying phase, joined together by slurrying and then fired. A special printing path was developed for printing the growth pattern, enabling non-planar printing with a vertically positioned nozzle.

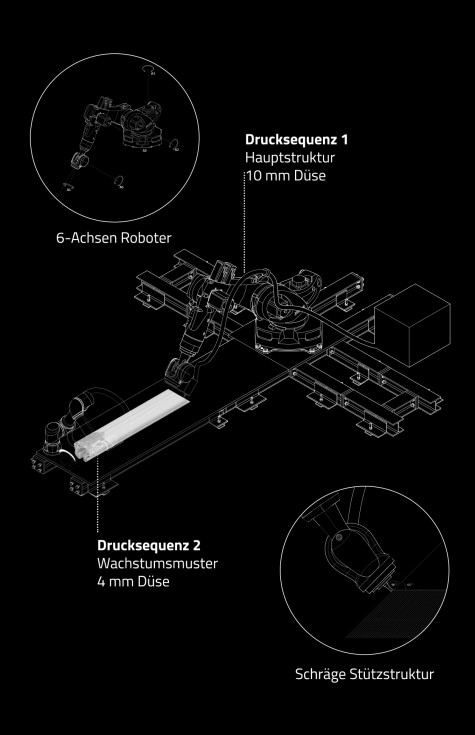

Scaled production

Unlike the 3D printer used for the prototype, the six-axis industrial robot enables non-planar paths to be printed using a sideways-mounted print nozzle. Production takes place in two consecutive printing sequences: First, the main structure is produced using a large-caliber nozzle (diameter approx. 10 mm). Since the growth pattern only achieves good sound absorption coefficients at low resolution, it is applied directly to the previously printed main structure in a second step using a finer nozzle with a diameter of 4 mm. The main structure itself is also manufactured on a 45-degree inclined plane in order to create a material-efficient geometry that does not require additional support structures. This method has already been presented by Wüthrich et al. (2021) and applied in practice by The New Raw (2025), for example. The modular components are ideal for prefabrication, which enables both higher production quality and time- and cost-efficient implementation.

Tests

The tests were done at the Acoustics Lab of the SAM Institute at TU Darmstadt. In the impedance tube, the fine-pored samples made with smaller nozzles showed way higher absorption values. Fired structures hit peak values of up to 86 percent at a frequency of 1600 hertz. Extra tests in the reverberation chamber confirmed how well it worked. Particularly in the frequency range between 500 and 1000 hertz, which is important for room acoustics, the prototype achieved absorption values of up to 84 percent. This proved that the geometry was effective both on a laboratory scale and on an architectural scale.

Outlook

Initial pilot projects in the field of 3D printing of buildings are already demonstrating the architectural potential of additive manufacturing. The approach developed in Silent Silhouettes builds on this by adding an acoustically effective layer to the wall structure. Future wall concepts could thus not only be material-efficient and structurally stable, but also optimized in terms of room acoustics.

This work has resulted in a prototype that combines acoustic and aesthetic functions. The combination of the main structure and porous growth pattern shows that purely ceramic material can be used to develop an effective, recyclable alternative to conventional acoustic foams. Silent Silhouettes demonstrates how additive manufacturing, materials research, and acoustic design can be brought together to make construction practices more sustainable.

References

Astrauskas, T., Januševiˇcius, T. and Grubliauskas, R. (2021). Acoustic Panels Made of Paper Sludge and Clay Composites. In: Sustainability, 13 (2).

DIN EN ISO 11654: 2018-05. Akustik – Bewertung von Schallabsorptionsgraden.

Fischer, H., Salonen, T., Mitterböck, M. and Korjenic, A. (2020). Untersuchung der hygrothermischen Eigenschaften eines ökologischen Bodenaufbaus aus Lehm. Bauphysik, 42(3).

Setaki, F., Tenpierik, M., Turrin, M., and van Timmeren, A.(2014). Acoustic absorbers by additive manufacturing. In: Building and Environment, 72.

Suárez, L. and Espinosa, M. M.(2020). Assessment on the use of additive manufacturing technologies for acoustic applications. In: The International Journal of Advanced Manufacturing Technology.

Wüthrich, M., Elspass, W.J., Bos, P., Holdener, S. (2021). Novel 4-Axis 3D Printing Process to Print Overhangs Without Support Material. In: Meboldt, M., Klahn, C. (eds) Industrializing Additive Manufacturing. AMPA 2020. Springer, Cham. https://doi.org/10.1007/978-3-030-54334-1_10

Supervision

Prof. Dr. -Ing. Oliver Tessmann

Max Eschenbach Dipl. Des.

Acknowledgement

I would like to express my sincere thanks to Prof. Oliver Tessmann and Max Eschenbach for their helpful contributions during the review process.

Special thanks also go to Ali Mohaved and Robert Feldmann from the SAM department for providing and supporting the measurements in the reverberation chamber and impedance tube.