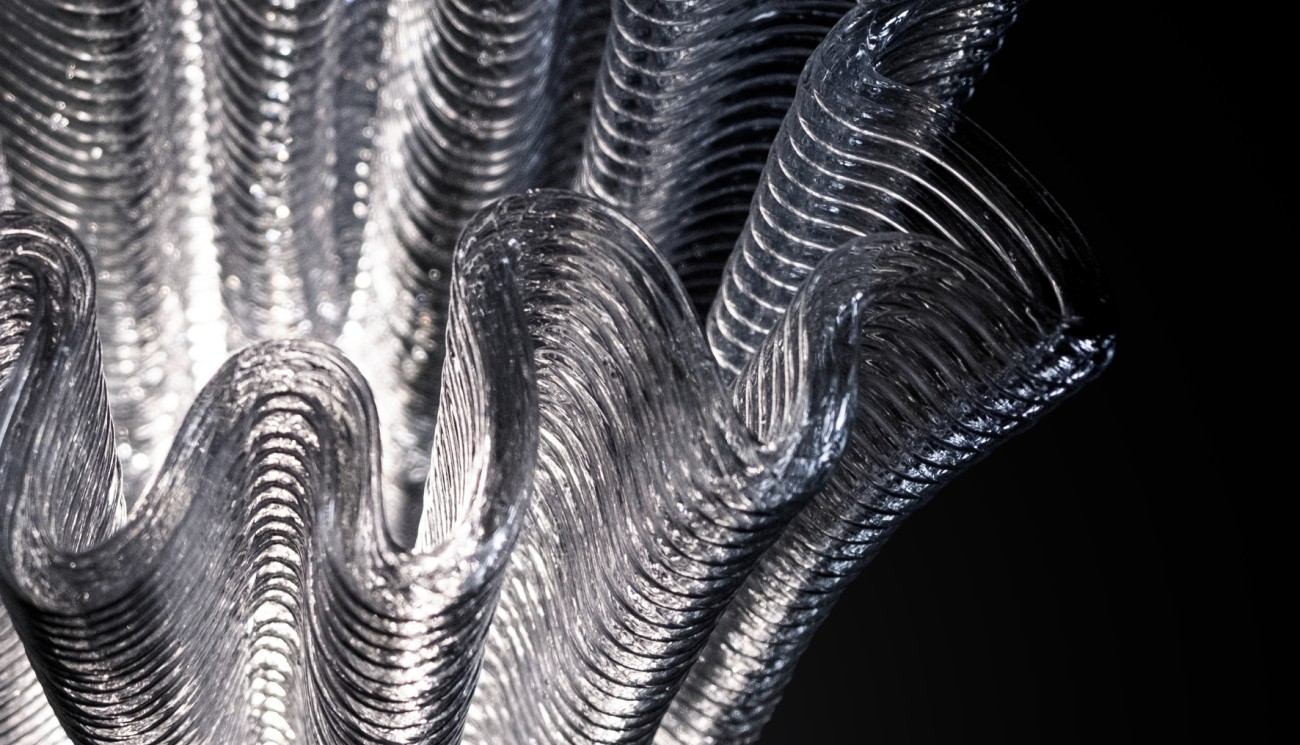

Multi-Material hollow-strands by Blow Extrusion (BX) 3D Printing

Blow Extrusion (BX) 3D Printing is an advanced additive manufacturing (AM) technique that allows 3D fabrication of robust, lightweight and hollow strands. The technique decreases material and resource consumption up to 85% compared to conventional extrusion based 3D Printing with solid cross sections. BX enables large-scale 3D printing with variable cross sections by controlling air flow during extrusion to inflate the strand. We developed BX using Fused Granular Fabrication (FGF) and Fused Filament Fabrication (FFF) combining multi-material 3D printing, blow extrusion, robotic fabrication, and computational design.

Project Aims

The challenges involved in the mechanical design of the print heads include (a) material throughput, (b) nozzle design and (c) precise control of the air for inflation. (a) To overcome the bottleneck of filament as feedstock in FFFBX we use four high push-force extruders and a sufficiently long melting channel to allow high volumetric flow. Four different filament feeding sources also enables multi-material printing. (b) Independent of the feedstock, the nozzles require a design that allows air to be introduced through the center of the molten material. We achieve this by using coaxial nozzles. (c) The desired outer diameter can be set from the ratio of extrusion speed, printhead travel speed and nozzle diameter, which results in the required air volume flow. A mass flow controller is synced with the extruders via a digital interface.

The digital process chain integrated geometric slicing, robotic simulation, and synchronized operation between a UR10 robotic arm and custom extruders. Using Rhinoceros and Grasshopper for parametric design and an open API for real-time coordination, the process enabled seamless control of extrusion, air pressure, and robotic movement.

Prototyping demonstrated material savings of 65% without expansion and up to 85% with 1.5x strand expansion through Blow Extrusion.

Initial tests explored maximum dimensions, variable hollow strand cross-sections, multi-material printing, and unsupported spatial 3D printing. Demonstrators, including columns, slabs, and walls, showcased automation potential and scalability for architectural applications.

BX reduces printing time, enhances scalability for architectural elements, and enables innovative designs by integrating material cavities and programming weight distribution within 3D-printed structures. BX significantly contributes to additive manufacturing for architecture, engineering, and construction, emphasizing sustainability and functionality.

Acknowledgements

The presented work is the result of interdisciplinary research at TU Darmstadt between the faculties of mechanical engineering and architecture, kindly funded by the “Forum for Interdisciplinary Research” (FiF) of TU Darmstadt under the project name “Luft nach oben”.

Team:

Digital Design Unit, (DDU), Department of Architecture, TU Darmstadt

Samim Mehdizadeh, Oliver Tessmann, Nastassia Sysoyeva

Institute of Printing Science and Technology (IDD), Department of Mechanical Engineering, TU Darmstadt

Philipp Wüst, Dieter Spiehl, Andreas Blaeser

IDD’s student assistants for manufacturing the demonstrators:

Moritz Birkner and Philip Gransow

Funding:

FiF Forum for Interdisciplinary Research , TU Darmstadt

More information about Mulit-Material Hollow-Strands by blow extrusion (BX) 3D printing can be found in the excerpt of the BE-AM Booklet 2024 (opens in new tab).