Rotoform – Development of a material system and research into its design potential for architecture

by Samim Mehdizadeh

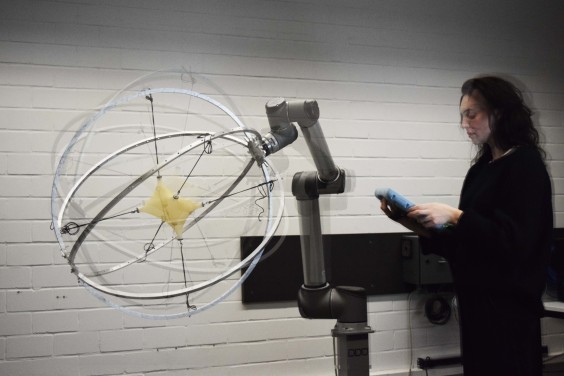

The thesis explores the design and fabrication of geometrically differentiated hollow nodal components that can be aggregated into larger structures. Samim designed the objects with the help of particle-spring models and fabricated them from an acrylic/plaster composite material that is cast into pre-tensioned hyper-elastic membranes that act as dynamic and flexible formwork. Since such a delicate formwork cannot withstand high pressure, only a minimum amount of material is cast. Subsequently the formwork is rotomoulded. The slow rotational movement distributes the material evenly across the formwork surface. The resulting lightweight components stay hollow or act as permanent formwork for a second cast.

Samim designed and prototyped a spatial structure consisting of multiple nodes and linear aluminum elements. He explores the geometric solution space of hyper-elastic membranes as formwork through digital simulation documented the process through phots, videos, drawings and diagrams.

In addition the thesis explores the design potential of RotoForm. Samim designed a ponton-like floating exhibition space at the RDM Pier in Rotterdam. The structures make use of the rotomoulded cavities that allows building to float on water. The building is changes location by floating to novel sites according to the urban development and transformation of the Rotterdam habour.