Integration of Mushroom Farming and Mycelium-Based Materials

Since the fungi used for producing mycelium materials are primarily wood-decay fungi, Pleurotus ostreatus (oyster mushroom) and Ganoderma spp. (Lingzhi/Reishi mushroom) are among the most commonly utilized species. These fungi are not only valuable for mycelium composite material production but also have direct applications for their fruiting bodies. For example, certain species of Ganoderma have medicinal properties and are already cultivated on a large scale in some countries. Similarly, oyster mushrooms are among the most widely consumed edible fungi.

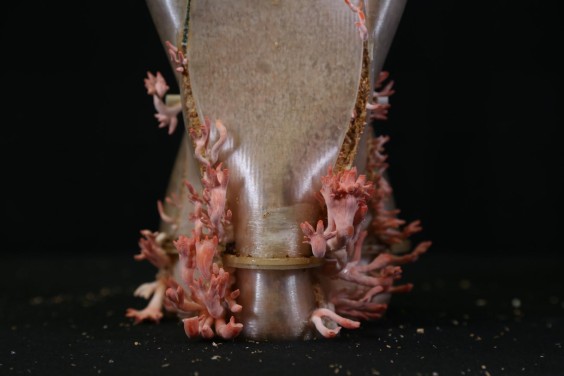

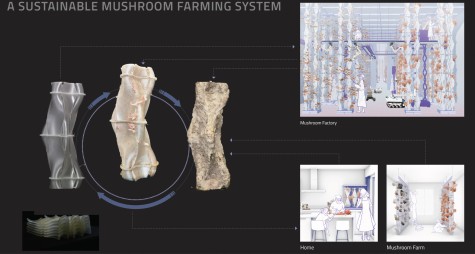

Thus, producing mycelium-based construction materials can be combined with mushroom cultivation for medical or nutritional purposes to generate synergies in resource consumption. This thesis suggests such a new model: a mushroom farm that not only harvests edible mushrooms but also utilizes the remaining mycelium for material production. To achieve this, the cultivation process would used 3d printed formworks or architectural mycelium components as growth enclosures, allowing the fungi to develop within these structures while leaving designated openings for the mushrooms to sprout. Once the fruit bodies of the mushrooms are harvested, the remaining mycelium blocks can be dried and repurposed as temporary construction elements.

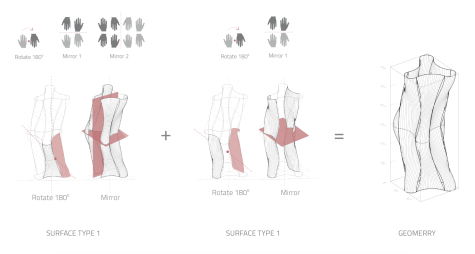

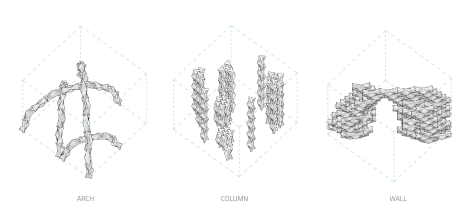

Module Design

The module geometry emerges from a series of rotation and mirroring transformations that lead to symmetric and interlocking shapes. The modules come with a variety of aggregation rules that lead to different assemblies such as arches, columns, and walls. This allows the mycelium blocks to be applied in a variety of diverse architectural scenarios.

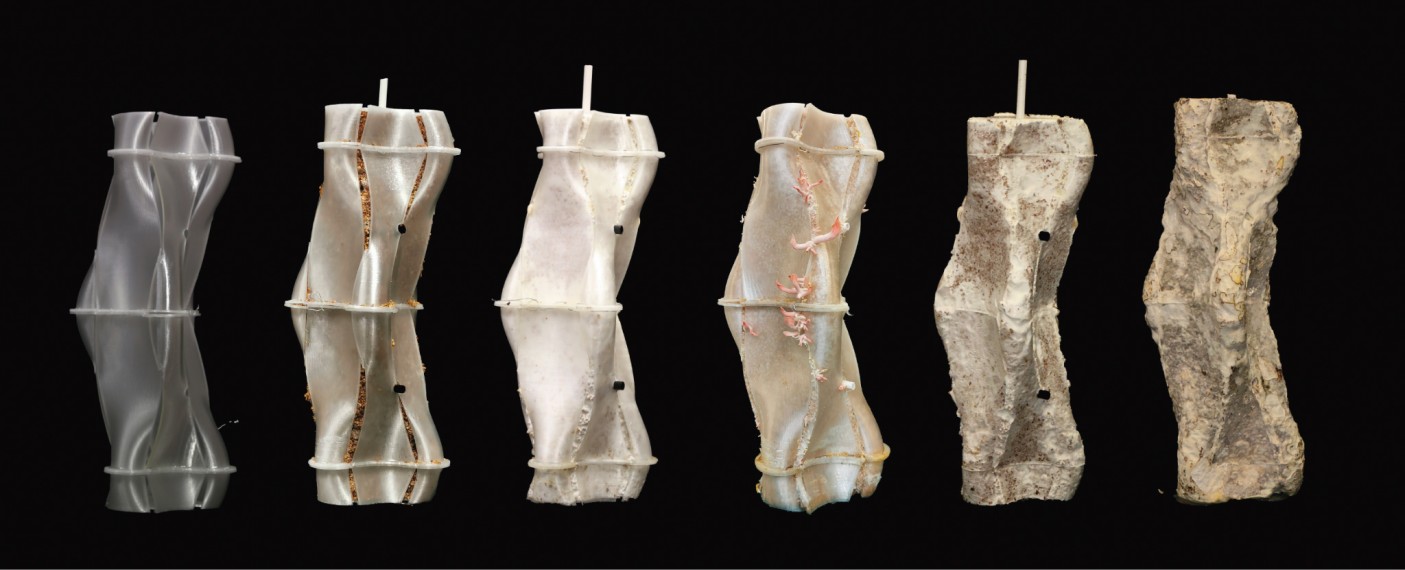

Fabricaton

The mold itself is made from modular elements. Thanks to the symmetry of the topological geometry, there are only two actual surface types, resulting in six mold pieces for fabrication. These six molds interlock at their nodes, forming a single-layer, stackable structure. Mold elements are connected using a wire to stitch pieces together.

To enhance adaptability and tolerance of mycelium block, the mold is slightly extended. This adjustment allows for more flexibility in different assembly scenarios. For example, when constructing an arch, the mold’s ends can be cut at an angle to fit the required shape.

Assembly

Two different methods of mycelial block assembly have been developed:Assembly based on post-stress systems and Assembly based on topologically interlocked geometric properties.

Post-Tensioned Assembly System uses mycelium blocks as components and flexible elastic cords as connectors. The cords enhance compression and friction between blocks, increasing structural strength. Unlike bolts or steel cables, elastic cords are soft, reducing damage to mycelium. This system offers high adaptability and flexibility, but requires full disassembly for modifications. Due to mycelium’s compressive strength and shear weakness, it is best suited for thick walls, arches, and ground-based structures.

Assembly based on topologically interlocked geometric properties uses bamboo to define mycelium block boundaries, as both are fast-growing and biodegradable. Though bamboo’s varying diameter makes modular design challenging, mycelium’s geometric adaptability allows seamless integration. It is a multi-tiered system, where mycelium blocks form small units, and bamboo frames enhance structural strength, compensating for mycelium’s weakness in tension and shear. This enables larger assemblies, easier unit replacement, and greater spatial diversity, supporting large-scale construction.

Sustainability

A Sustainable Mushroom Farming System

In the future, a fully automated mycelium farm managed by robots could redefine sustainability. Suspended mushroom units would produce medicinal Ganoderma and edible oyster mushrooms as primary agricultural products, while the leftover mycelium blocks would be dried and processed into biodegradable building materials as secondary products.

Additionally, households and farms could purchase mushroom-growing kits, and community mushroom-sharing pavilions could be established. Residents would independently cultivate and harvest fresh mushrooms, while the dried mycelium blocks could serve as temporary building components or be used to replace the pavilion’s outer walls. This system seamlessly integrates agriculture and architecture while providing an educational platform for children.

Furthermore, mycelium molds could be shared online, enabling people to 3D print and DIY their own mushroom kits and bricks, expanding the circular system globally.

The Mushroom Pavilion: A Community Interactive Installation

Designed as a community hub, the mushroom pavilion features integrated cultivation units, a mycelium-based facade, and a bamboo frame structure. This eco-friendly installation is equipped with solar panels and a rainwater harvesting system, ensuring self-sufficient energy cycles. The pavilion provides a sustainable source of edible mushrooms while serving as a temporary construction resource—when the exterior mycelium bricks degrade, they can be easily replaced, reinforcing the closed-loop design.

Supervision

Oliver Tessmann

Nadja Gaudilliere

Mirko Dutschke