Rotoform Studio

In this studio participants designed and prototyped innovative concrete formwork systems that use resourceefficient strategies to make new shapes of concrete elements possible. The work is based on rotoforming concrete in hyperelastic membranes, a process developed by the Digital Design Unit (DDU) of the Technische Universität Darmstadt.

Rotoforming is a production process in which a minimal amount of liquid material is poured into a mould. The material is coats the wall of the slowly rotating formwork, but does not fill the entire mould. When used for casting concrete, the small amount of liquid material significantly reduces the hydrostatic pressure that acts on the formwork. The process thus unlocks a completely new range of resource efficient, lightweight formwork materials. We conceive of rotoforming as a material system in which form, material, structure and its synthesis (materialization, fabrication and assembly) are regarded as integral and closely linked elements. Computational tools and techniques, as part of this system, allow notating and instrumentalizing the intricate interactions between form, material, structure and environment within the architectural design process.

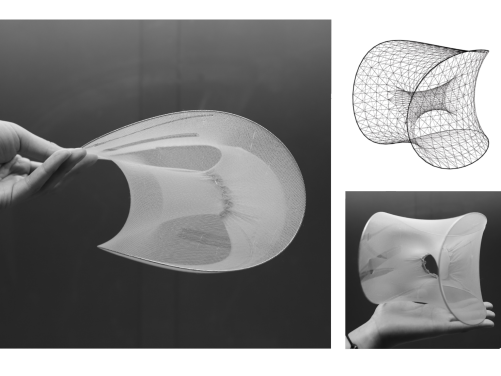

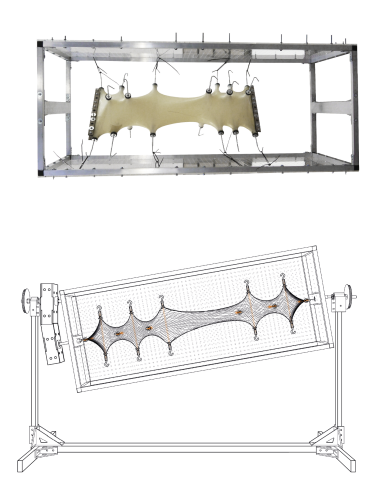

)( Co-Forming

Luisa Ramirez, Jiawen Yuan, Xiaolin Yue, Maylin Yuka

)( Co Forming examines interactions between bent boundaries for prestressing membranes. The membrane performs under tension while the boundary is a bending element in the system. In such an intricate equilibrium the membrane bends the boundary into a shape while the boundary prestresses the membrane. Together the systems form a complex cavity for casting and rotoforming.

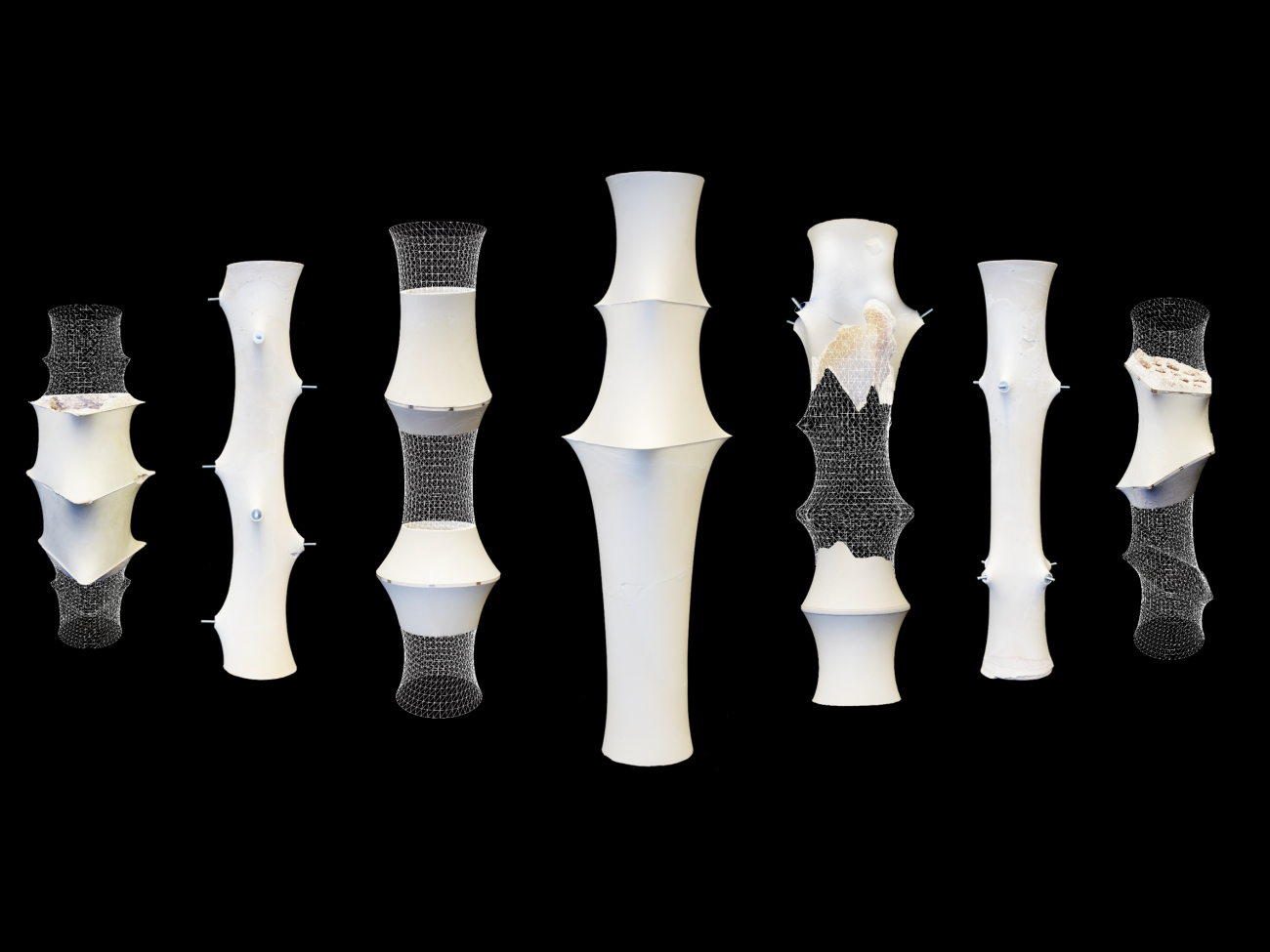

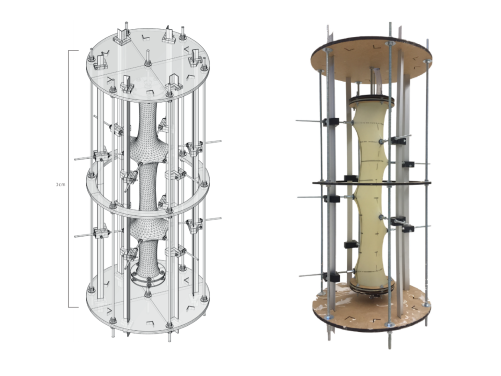

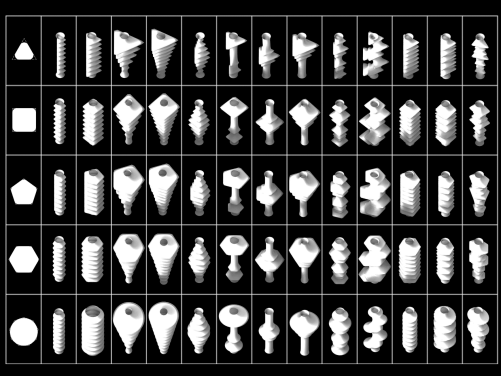

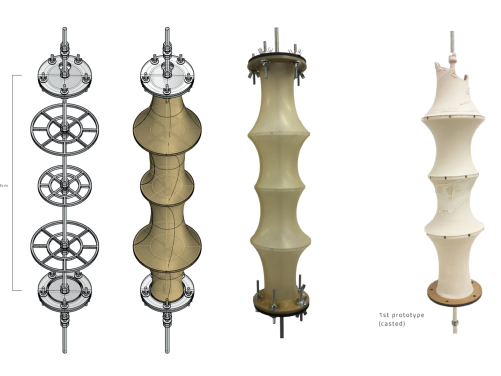

Roto_Column

Janine Junen, Leonard Fatio , Anna Mytcul, Ece Ulu

The Roto_Column team produced a broad range of columns based on latex sleeves prestressed through internal compression elements and external tension elements. An adaptable jig allowed the team to quickly produce differently shapes columns.

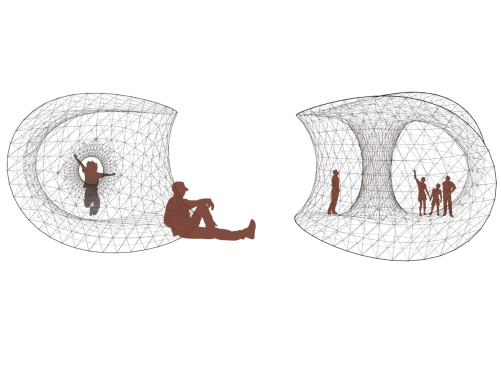

Cube Space

Boyang Ji, Zhili Xia, Dawei Xin, Liangyan Xu

Cube Space combines a modular system von voxels with hyperboloid surfaces. Initial design explorations were conducted using arrays of wires to form hyperboloid surfaces. These quasi-surfaces were able to penetrate each other, similar to digital surface models. The aesthetically striking models, however, could not be translated into membrane formwork but were a good starting point to explore concepts of prestressing. When changing from wire to membrane the twelve edges of a cube and twelve diagonals on its six faces act as possible boundaries for prestressing membranes. A membrane hyperboloid is formed between two edges that are not coplanar. Within the rigorous spatial grid a multitude of shapes is possible. The resulting surfaces become the membrane formwork for rotoforming. The edges of the cube that were used as boundaries become part of the element. Similar to concrete-steel composite elements they allow for a precise connection detail between modules. The team explored the combinatorial potential of the cube space with simple translational operations such as copy, move, rotate and mirroring.

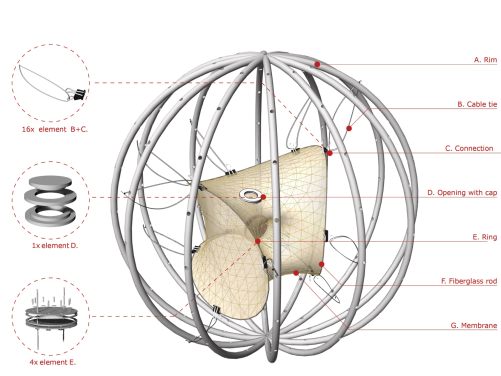

Dynamic Form(ing)

Shakeu Addallah, Danial Ahmad, Jianpeng Chen, Yijun Wang

Dynamic formwing is a membrane formwork system for a rotoforming process that is inspired by the concept of tensegrity. Tensegrity is a structural principle in which isolated compression members are connected through a network of tension elements such as cables or membranes. The intricate balance between tension and compression generates flexible and lightweight systems. The term tensegrity was coined by Buckminster Fuller and integrates the two words “tension” and “integrity”. Dynamic formwing exploits the concept by combining hyperelastic membranes with compression members to form cavities for casting liquid material and rotoform elements. Compression members become permanent parts of the cast to form composite building elements.

Form Follows Sequence

Liana Araklejan, Azra Licina, MarcelForberg

The idea of the project is based on the geometry of the invertible cube of the mathematician Paul Schatz. This geometry consists of two outer latch pieces and the middle belt part. The belt geometry consists of six sub-tetrahedrons, each with four surfaces and six edges. By arranging the tetrahedra at the connecting edges, the body can be rotated infinitely in one direction. The invertible cube is a rotoforming machine in its own right. Its infinite movement produces several rotoformed elements at the same time. The individual tetrahedron became the framework for our formwork systems. Three approaches can be pursued: The generation of volumes based on the entire tetrahedron, subtractive bodies, by using the edges of the tetrahedron as a frame to carry anchors of linear tension elements. In the project an initial weakness was turned into a major design feature: When prestressing a membrane in only one direction, drapery forms emerge. The team’s aim was to control and consciously design these shape in order to create the interesting contrast of a cast material having a textile appearance.

Participants:

Shakeu Addallah, Danial Ahmad, Liana Araklejan, Jianpeng Chen, Leonard Fatio MarcelForberg, Boyang Ji, Janine Junen, Azra Licina, Anna Mytcul, Luisa Ramirez, Ece Ulu, Yijun Wang, Zhili Xia, Dawei Xin, Liangyan Xu, Jiawen Yuan, Maylin Yuka, Xiaolin Yue

Tutors:

Samim Mehdizadeh, Oliver Tessmann, Annie Locke Scherer, Roger Winkler

Jury:

Ariel Auslender, Sculptural Design Unit, TU Darmstadt

Philipp Eversmann, Experimentelles und Digitales Entwerfen und Konstruieren

Moritz Dörstelmann, FibR GmbH

Manuel Pfänder, Sculptural Design Unit, TU Darmstadt

Andrea Rossi, Experimentelles und Digitales Entwerfen und Konstruieren

Fabio Scotto, Gramazio Kohler ETH Zürich

Vasily Sitnikov, KTH Stockholm